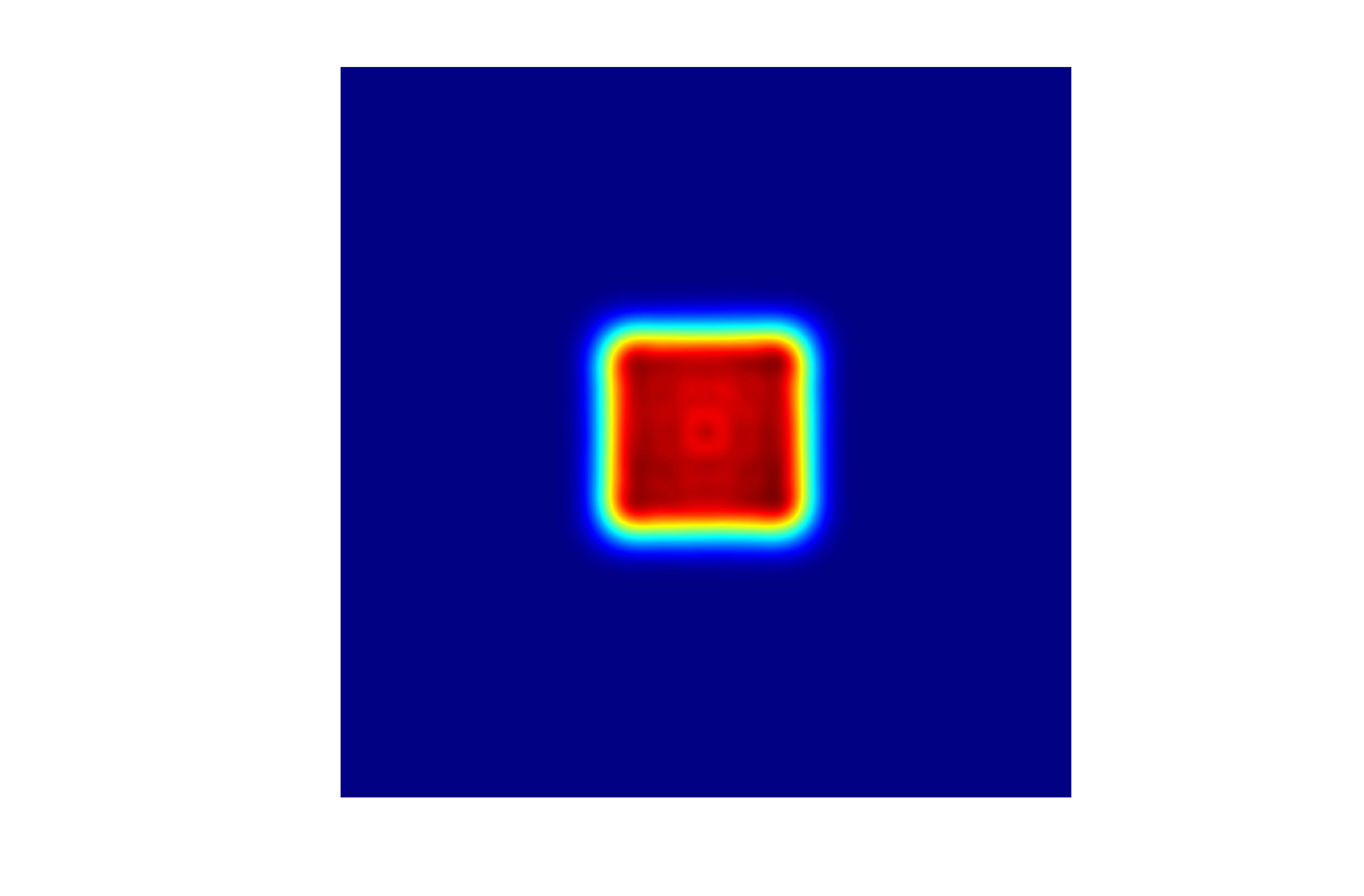

Implementing beam shaping techniques further enhances the performance and capabilities of ultrafast lasers for thin film (and other forms of) material processing. Ultrafast lasers are an expensive laser light source and beam shaping can optimize the throughput efficency of the process. Beam shaping can also lead to lower defects in the process. Options with PowerPhotonic beam shapers include optics for changing the beam shape (e.g. from round to square) and for changing the beam profile (e.g. from Gaussian to top-hat). A single beam shaper can perform both of these functions.

As well as very precisely and completely removing thin films, ultrafast lasers can instead modify surface texture at the nano-scale and make (for example) hydophobic surfaces.

Thin film processing using ultrafast lasers is a cutting-edge technique that allows for precise modification and fabrication of thin films on a nanoscale. This process utilizes ultrashort laser pulses to selectively remove or modify thin film materials, offering unique advantages in terms of precision, speed, and versatility.

The process of thin film processing begins with the generation of ultrashort laser pulses, typically in the femtosecond or picosecond range. These pulses have extremely high peak powers, allowing for efficient interaction with thin film materials. The laser pulses are directed onto the thin film surface, and their high intensity enables various processing effects depending on the desired outcome. What sets apart materials processing with ultrafast lasers compared to other longer pulse lasers (or CW lasers), is that the energy in a single pulse is extremely low. This means that negligible heat goes into the material being processed and the surrounding material is not affected in any way. This level of precision is crucial in applications such as microelectronics, optics, sensors, and energy storage.