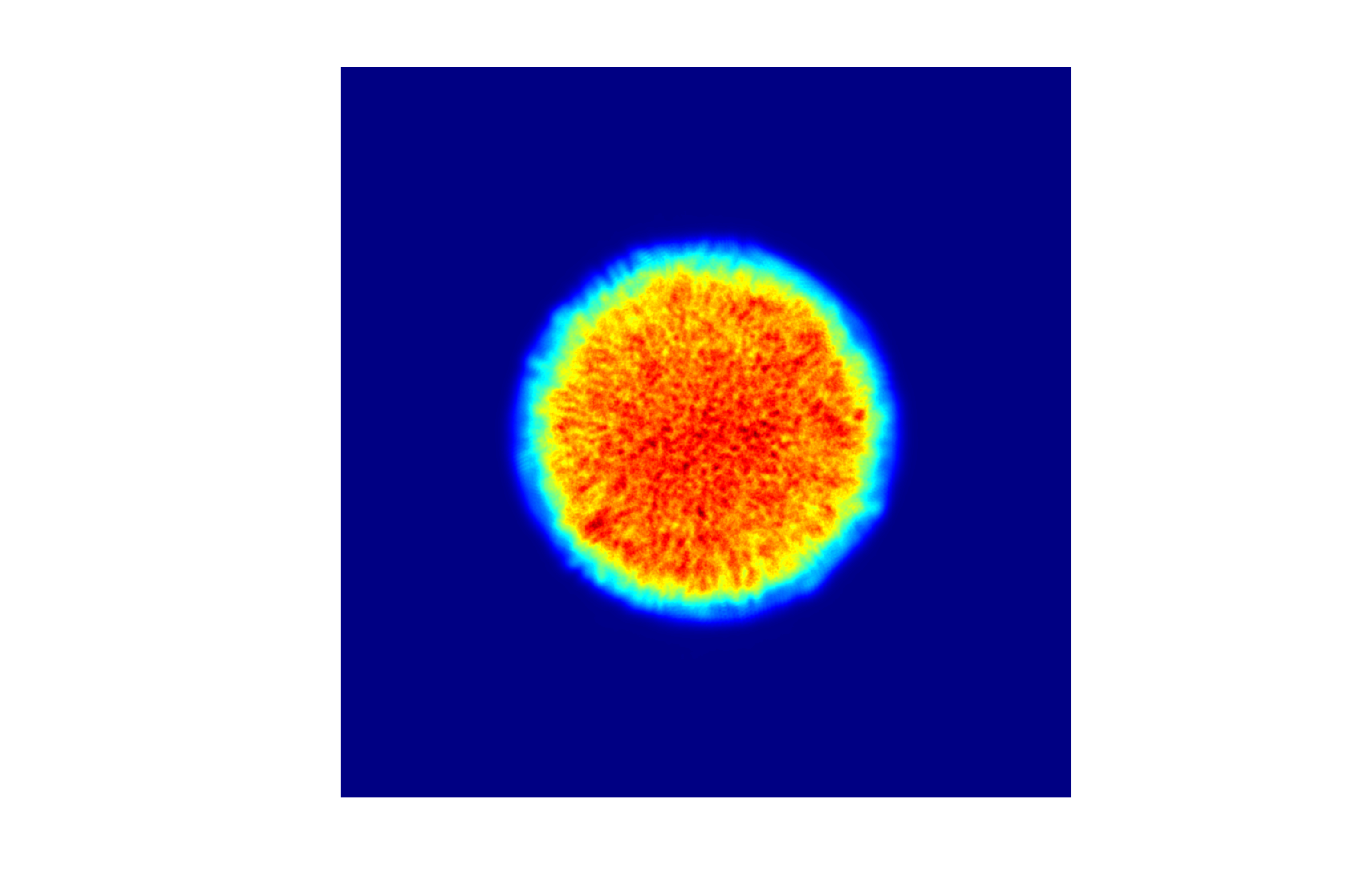

PowerPhotonic has a number of products designed to enhance laser cutting processes. When cutting thick sheet metal (15mm or thicker), a ring shaped spot is often used. The ring can be generated from an axicon style beam shaper, or dual core fiber can be used. Our “Light Tunnel Generator” product is a singe optical component that is added inside the laser cutting head. It produces a ring at focus, but unlike axicons and dual core fiber, the ring from the Light Tunnel Generator has a much longer depth of focus (approx 4 times longer). This extended depth of focus can enhance the laser cutting of thick metal sheet; making high quality cuts AND using significantly less power than dual core fiber solutions.

Laser cutting is a precise and efficient method for cutting various materials, including metals. When it comes to thick metal cutting, laser technology offers several advantages over traditional methods like plasma or mechanical cutting. Laser cutting involves the use of a high-powered laser beam focused on a small spot to melt, burn, or vaporize the material. For thick metal cutting, lasers with higher power levels are employed to overcome the increased material density. These lasers are typically solid-state lasers, such as fiber lasers or disc lasers.

The process begins with the generation of the laser beam, which is then guided through a cutting head. The cutting head is usually made up of a collimating and focusing lens, used to define the size of the beam at the surface of the metal. The laser beam is tightly focused onto the metal surface, creating a high-intensity heat source that rapidly melts or vaporizes the material. Simultaneously, an assist gas, such as oxygen or nitrogen, is delivered through the cutting head to blow away the molten metal and debris from the cut zone.

Thick metal cutting requires careful consideration of several factors. The laser power, beam quality, and cutting speed must be optimized to ensure efficient and precise cutting. Additionally, the choice of assist gas and its pressure greatly influences the cutting process, as it affects the removal of molten material and the resulting cut quality.