Contact Us for more information on this product.

Description

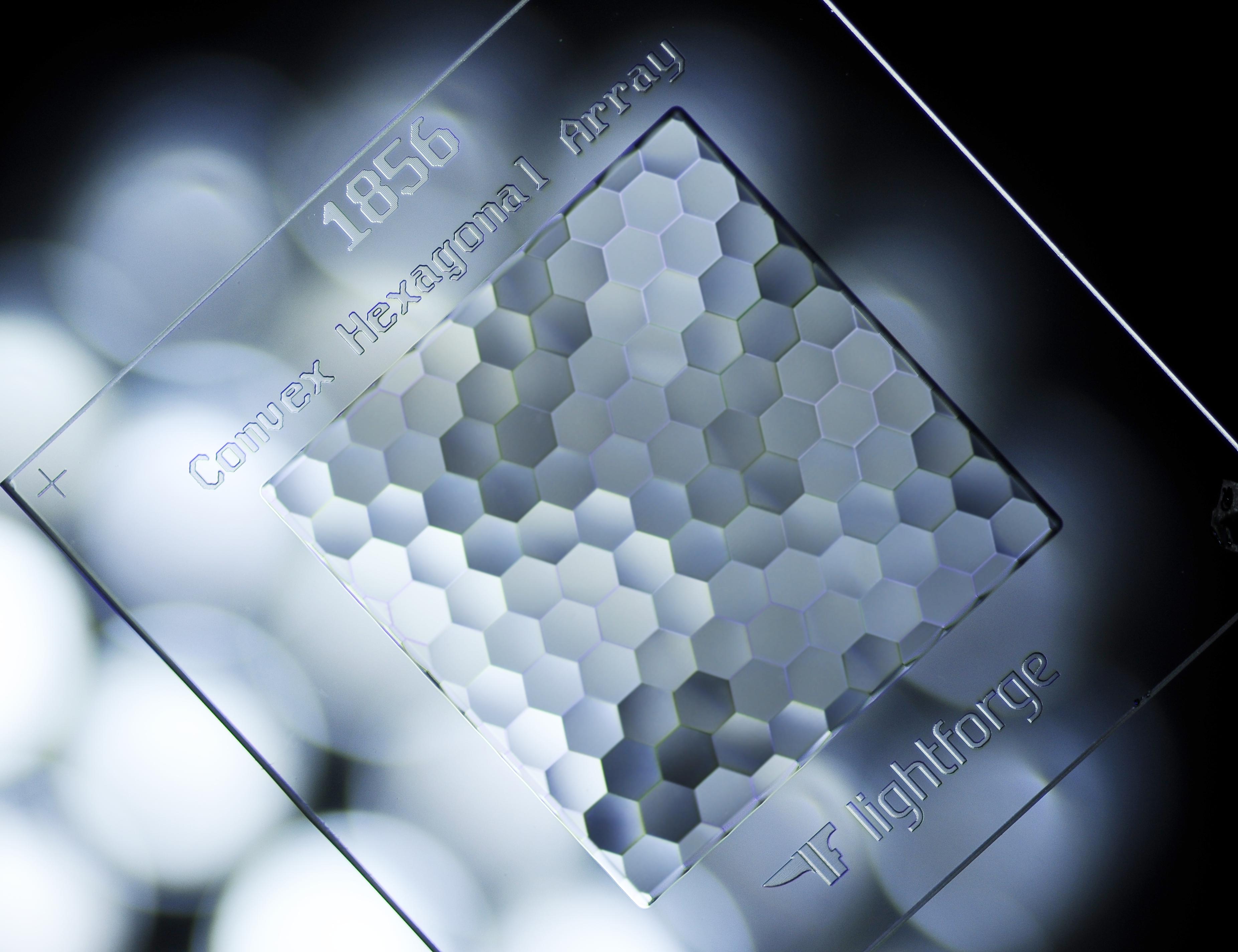

LightForge™ is a low-cost rapid prototyping service that gives optical designers the ability to create innovative new freeform surfaces, test new ideas, and verify designs for production without incurring expensive upfront engineering charges and lengthy prototyping lead times.

Uploading a design to the LightForge™ website could not be simpler. The optical surface must be specified on a 10-micron grid for x, y, and z. After submitting the design, the LightForge™ website runs a design rule check, and if accepted, your optic could be ready in as little as two weeks.

LightForge™ can be used to create a wide range of refractive optical elements, from microlens arrays to completely custom freeform surface shapes.

Whether you need rapid prototyping or one-off designs, LightForge™ caters to your requirements. Utilize the clear aperture of your optic to conduct thorough testing and verify performance. Prepare your designs for volume production or embrace the benefits of a single prototype.

If you are an optical designer who needs to create custom optical surfaces quickly, affordably, and with high quality, then LightForge™ is the perfect solution for you.

Product Spec Sheet

Key Features

- Completely Freeform Design

- Fast Turnaround Time

- High Power Handling

- Easy to Integrate

Benefits

- Low-Cost Prototyping

- Repeatable Surface Creation

- Design Freedom

- Design Control

Target Applications

- Research and Development Trials

- University Trials

- Laser Material Processing

- Laser Projection